The RIMA Group is the only primary magnesium producer in the Southern Hemisphere and the only one in the world to produce automotive parts from the ore in a highly verticalized process. Operating a unique, verticalized and highly efficient extra-high vacuum silicothermic process, RIMA began primary magnesium production in 1981 and is currently the 3rd oldest and most traditional magnesium producer in the world. With a production of 23,000 t/year of magnesium metal and alloys, the RIMA Group accounts for around 2% of the world's primary magnesium production and is one of only 6 primary magnesium producers outside China.

As magnesium is the lightest of the structural metals, with a density of approximately 1.7g/cm³, its use brings several advantages, reducing the final weight of a part by up to 30% compared to similar parts made of aluminum (with a density of 2.7g/cm³). This characteristic allows the production of structures used in everyday life in lighter and more efficient versions, such as in cars, where magnesium provides lower fuel consumption and thus reduces atmospheric emissions.

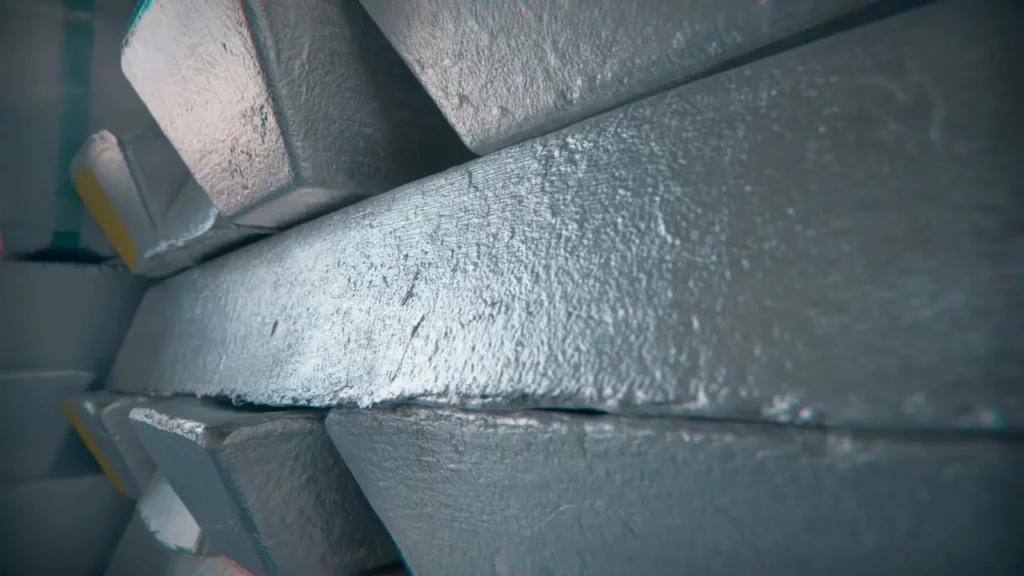

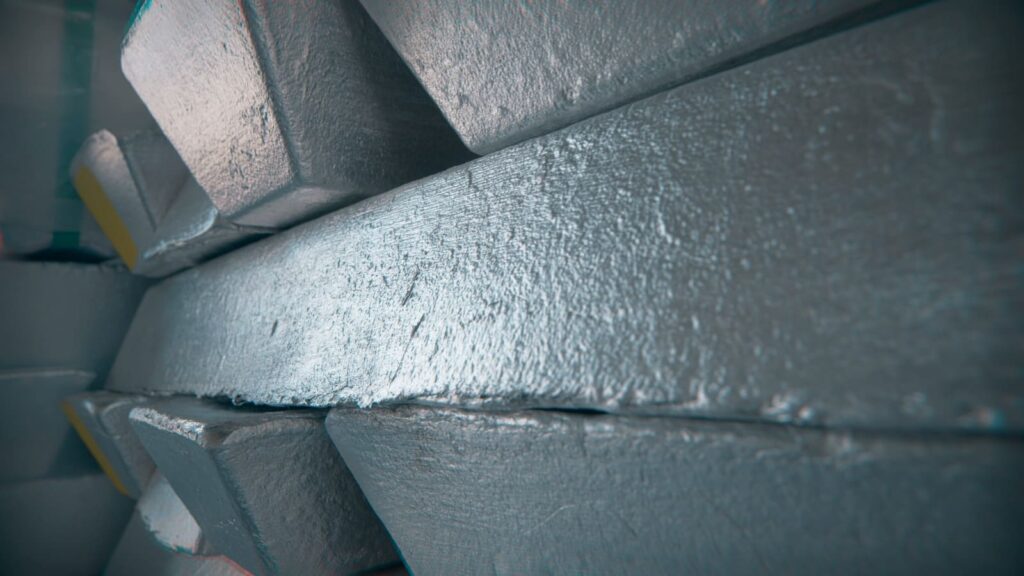

The RIMA process uses dolomite (MgCO₃:.CaCO₃:) as the raw material for magnesium production The dolomite is calcined in a rotary kiln and reduced by silicon, pressed, and this mixture is charged via reactive columns in internally heated electric furnaces operated under extra high vacuum. The magnesium metal produced in gaseous form condenses in a cold chamber in its raw form, called magnesium crystals. This Magnesium Crystal is then melted, refined and cast into its final form as Primary Magnesium ingots with a minimum 99.80% Mg or following the chemical specifications of the different Magnesium Alloy families.

RIMA produces a complete range of magnesium products, including magnesium metal ingots, different alloys, magnesium powder of different specifications for various applications in the chemical, refractory, welding and termite industries, etc. In the magnesium powder segment, magnesium's main application is in the desulphurization of pig iron in steel companies.

It is an important alloying element used by the aluminum industry, mainly in the production of automotive parts, extruded and rolled products, such as beverage cans. Magnesium is also used as a reductant in specialty metals such as zirconium and titanium, as well as in refractories, welding, warfare, pyrotechnics, cathodic protection, specialty chemical reagents and other industries.

Magnesium is a strong nodularizing element in cast iron and is widely used by the ferrous casting industry in its metallic form (nuggets) or as the main element in the Magnesium Ferro Silicon.

Magnesium in powder form, mixed with other materials, is increasingly used as a desulfurizer in the steel industry. This product offers the best performance and cost/benefit ratio in the following cases:

The most commonly used desulphurizing mixture consists of magnesium powder (below 1mm) and micro pulverized lime. Depending on the injection technology applied and the time available to achieve the required sulphur content in the final product, the percentage of metallic magnesium can vary, so RIMA customizes its product for each client and their respective process.

RIMA produces and supplies sophisticated equipment for mono-injection, co-injection and sequential injection of magnesium-based mixtures for pig iron desulphurization in torpedo cars and transfer pans. To this end, the RIMA Group maintains a team of specialized technicians and engineers who provide the customer with all the necessary support and assistance.

We won the "IMA Award of Excellence - Environmental Responsibility 2023" for having the most sustainable magnesium production process in the world!