The products manufactured by the RIMA Group's Ferroalloys division have many applications in various industries, especially in the steel industry for in the production of electrical steels and high mechanical performance steels.

RIMA is the world's second largest producer of High Purity 75% Ferro Silicon , also known as FeSi75 HP. It is composed mainly of iron and silicon, characterized by a high degree of purity in relation to other elements such as Ti, Al, C, Ca and P, making it ideal for the manufacture of noble, high value-added steels such as electrical steels. Due to its low presence of contaminants, RIMA's FeSi HP is suitable for the most controlled processes and the most demanding end customers in the USA, Europe and Asia.

Today, RIMA is the 2nd largest producer of Calcium Silicon (CaSi) in the world. CaSi is used as part of the steel refining process to deoxidize and desulphurize the metal, as well as to modify the alumina inclusions often present in the bath.

Through these actions, various improvements in mechanical properties are promoted, such as increased resistance to corrosion and wear, improved performance in extreme temperature conditions (both high and low), increased resistance to impact and fatigue, among other benefits.

It is widely adopted in steel mills around the world due to its low concentration of harmful elements such as aluminum and oxides, which is achieved through strict controls of its processes and raw materials.

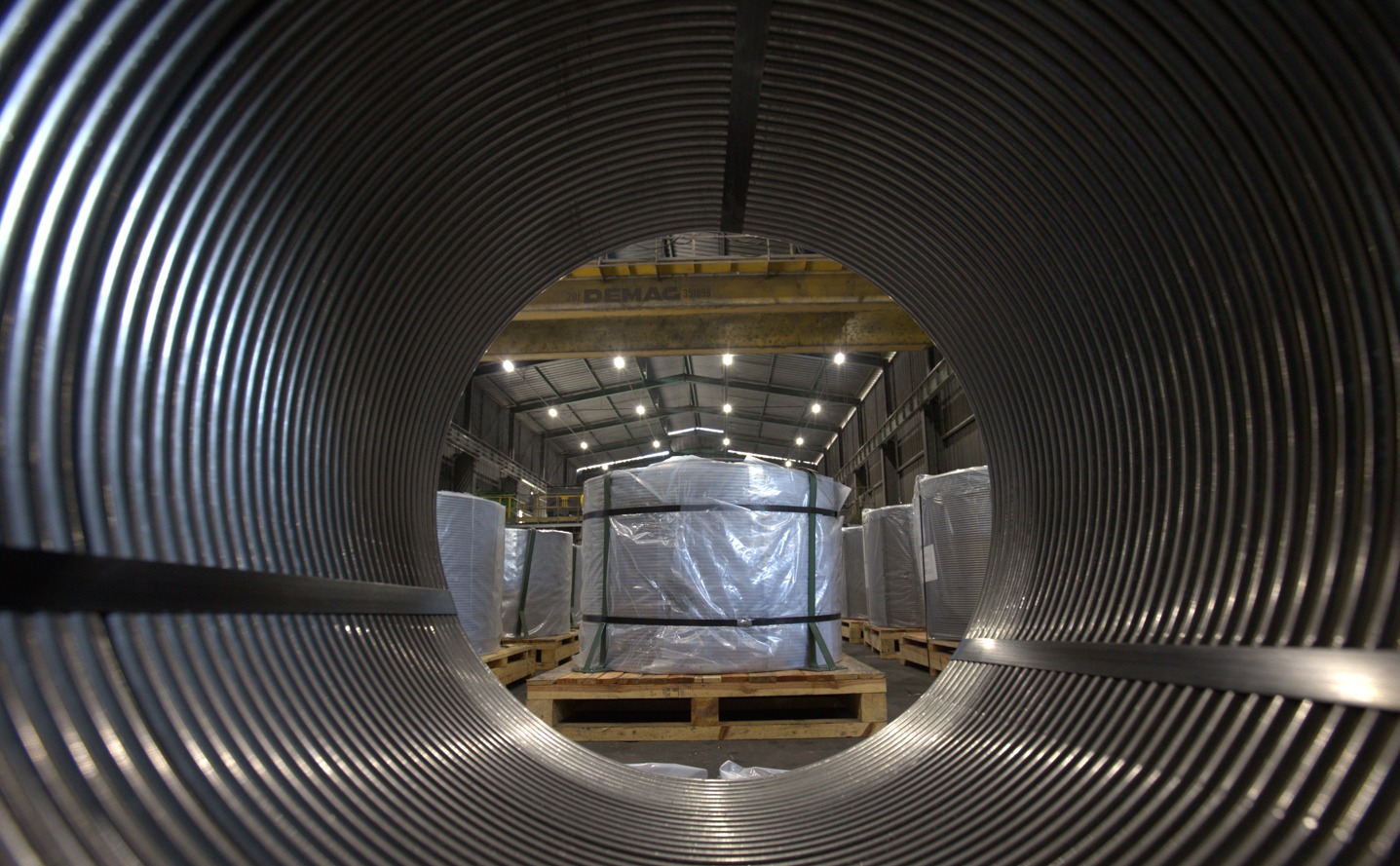

Cored wire for steelmaking is a metal tube filled with ferroalloys used in metallurgy to introduce alloying elements, deoxidizers, and modification agents into liquid steel. This method provides an efficient way to deliver these additives during the metal refining process.

The use of Cored Wire offers several advantages over other addition methods. It allows more precise control of the amount of additive added to the molten metal, resulting in a more consistent composition. In addition, the use of Cored Wire reduces melting time and increases process efficiency due to rapid dissolution in the steel.